Report on

Conservation works undertaken on the Dovecote, Bruton.

November 2010.

Contractor: Renˇ Rice.

Client: The National Trust.

1.

Introduction.

The history and

general description of the building are more than adequately covered in the

archeologistÕs report so they will not be entered into here except where

necessary to provide background information about conservation choices made

during the project. The most salient point is that the four sided tower, once

roofed now has no roof leaving exposed wall tops on the four gables, three of

which remain.

The second most

salient point in relationship to choices of scope and method of the works

relates to budget. A full top to bottom, interior and exterior conservation

project was not possible and budgetary restrictions limited the work to the top

third of the tower with special emphasis on cappings and the stitching of

cracks/bulges.

Pre-contract

photographs can be found in the pre-contract photographic survey folder on the

disc.

2. Scope of the

Works.

2.1.

Gable crosses

2.1.1

West gable

All hollow joints

were filled- methods and mixes dependent on scale of fissure. Areas of the

concrete capping beneath the gable cross were cut out and replaced.

2.1.2. South gable

All hollow joints

were filled- methods and mixes dependent on scale of fissure. Areas of the

concrete capping beneath the gable cross were cut out and replaced.

2.1.3 East gable

All hollow joints

were filled- methods and mixes dependent on scale of fissure. Areas of the

concrete capping beneath the gable cross were cut out and replaced.

2.2. Cappings: concrete

2.2.1. Cutting out and replacing loose concrete

capping.

North

(truncated)gable

East gable

Junction of north and west gables

south west

corner

2.2.2. Drilling

through capping and grouting wall

top.

After pointing up

localized walls to avoid grout runoff 25mm holes were drilled through the

concrete capping and grout composed of nhl 3.5 hydraulic lime and sharp sand

with water was introduced via

funnel into the holes. In total some 15 buckets of grout were poured

into the wall tops.

2.3. Vegetation

removal and subsequent masonry rebuilding.

All woody growth

was removed from the building and areas were dismantled where necessary to

chase out roots, esp in the north west corner.

2.3.1.a

North west corner

Subsequent to the

last picture above the Elder root

to the bottom left was cut out and minor roots drawn from the interior of the

masonry. All stones had been stored in order and were rebuilt in reverse order.

The exterior

facework of the north (truncated) gable was poorly bonded to the core so 8mm

stainless threaded bar was inserted and resined into joints as the internal

masonry build progressed. In all 3no bars were fixed as the build progressed.

Rebuild:

Subsequent to the

rebuild of the masonry and the repositioning of the original reclaimed stone roofing the area was recapped with

concrete to match the existing. (see photograph above)

2.4. Works to

masonry surfaces

2.4.1. Grouting small cracks with syringe and

clay birdsnests using St Astier Coulinex grout. (Coulinex product information

sheet on disc.)

Mix: Approx 1

Coulinex to 0.8 part water.

It was not always

easy to introduce grout into the smallest of the cracks but where possible a

catheter syringe was used with a clay seal. Where gravity feed was possible,

clay birds nests attached to the masonry were filled with liquid grout which

was encouraged to flow into the pre-wetted crack.

2.4.2. Grouting larger cracks using grouting gun and soft sand with nhl 3.5

For the larger

cracks of 4mm and above a grout gun was used with a 5mm nozzle using a mixture

of soft sand and St. Astier nhl 3.5 hydraulic lime. This

was mixed to a gunnable consistency with water mechanically in a clean bucket.

At the highest

levels, most exposed, the nhl 3.5 was substituted with nhl 5.

Mix: 1 part nhl 3.5: 2 parts soft yellow sand : water

2.4.3. Pointing and joint filling using coarse

hydraulic lime mortar mix

Larger open joints

and other lacunae were filled with coarse lime mortar in normal pointing style.

Mix: 1 part nhl 3.5: 2 parts Chardstock sand: 1. Part Bath Stone Dust washed: 0.25 part crushed coal

(this started out as 2 parts Bideford grit: 1 part Portland Dust: 0.25 parts crushed coal but this was too grey and too coarse)

At the

highest levels, most exposed, the nhl 3.5 was substituted with nhl 5.

2.5. Insertion

of Cintec ties.

Six ties were inserted in the eastern

corner of the south wall where there was a pronounced bulge in the masonry

(See Mann Williams report)

2.5.1. South

Wall east corner

North wall west corner

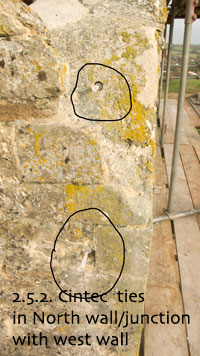

2.5.2. A further two ties some 2m in length were

inserted into the north wall at itÕs abutment with the west wall to tie the two

walls across a vertical crack ( see Mann Williams report)

The works extended

from the apex of the gables to a point some 6 metres below both interior and

exterior.